Our products

With 18 years of focus on ultra-fine ultra-pure crushing and classifying research, powder shape control,

powder surface modification, and system integration of powder engineering equipment,and provide customers with complete solutions.

Jet Mill

The first Chinese large-scale Jet Mill grinding equipment, has two structures: vertical and horizontal, which help customers to develop market.

Steam Jet Mill

The nano-scale & sub-micron pulverization of the dry process can be realized, the problem of big air viscous force and product agglomeration can be effectively solved.Steam Jet Mill

S-MQW Horizontal Steam Jet Mill

S-MQL Vertical Steam Jet Mill

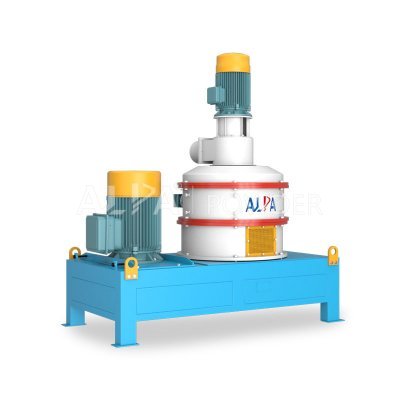

Impact Mill

The particle size range is from 20 mesh to 3000 mesh, production capacity is from 5kg/h to 5000kg/h. The cold air, air circulation and nitrogen circulation process can be selected.

Air Classifier

The vertical multi-rotor classifier, suitable for precise classifying of different materials.

Laboratory Equipment

The first combined structure of Jet Mill, Air Classifier and Impact Mill. High efficiency airtight seal, small footprint, easy operation and wide application.

Powder coating and surface modification production line

The modifier has a small amount of use, high coverage rate, high degree of automation, flexible production process, environmental protection and energy saving, abundant equipment selection and customizable solutions.

Classifying and Ball Mill Production Line

Large-scale, intelligent, energy-saving, low-carbon, environmentally friendly, reasonable production capacity, large output, stable operation, stable product quality.

Auxiliary Equipment

Can be used together with various types of jet mills, Impact Mills and Classifiers to meet the demanding requirements of the closed operation.Auxiliary Equipment

AVC Vacuum Conveyor

DFS Dust Free Feed Bin

Other Auxiliary Equipment

Lets meet and talk!

[email protected]

Who chose us?

37 companies listed in 500 international top-class ones , 89 companies listed in 500 Chinese top -class ones , 169 national level key laboratories and other customers are more than 3000,is a silent compliment to us.

News

Based on our own development, whether it is ALPA news, industry hotspots, customer sites or technological innovations, we will present them to you in the first time.

New year comes! 2020, look back on ALP A wonderful moment

Time flies, the end of the year in a blink of eyes.This year, we survived the Covid-19.This year, we grew up amidst difficulties.This year, we ushered in the tenth anniversary with the joint efforts of all ALPA people.

Grateful to meet, thanks for being there

2020 something unusual. It feels good because of your companionship. Thanks giving Day, I’ve been different from the usual. These words come from my heart, please listen attentively.

Opening of POWTECH 2019 – ALPA unveiled at the Nuremberg exhibition.

On the 9th April, POWTECH 2019 International Powder Machining Equipment and Instruments Exhibition was officially launched in Nuremberg, Germany. With 823 exhibitors from 35 countries bringing together the Nuremberg Exhibition Center.

Promotional video

Poetry,Is a voice that cannot be described by words.Music,Is the voice of the fiery soul.Painting,Is a voice that the eyes cannot make.Creation,Is a voice that a creator is ought to make.Story,Is a voice that a striver makes to express opinions.