Unique Advantages

Working Principle

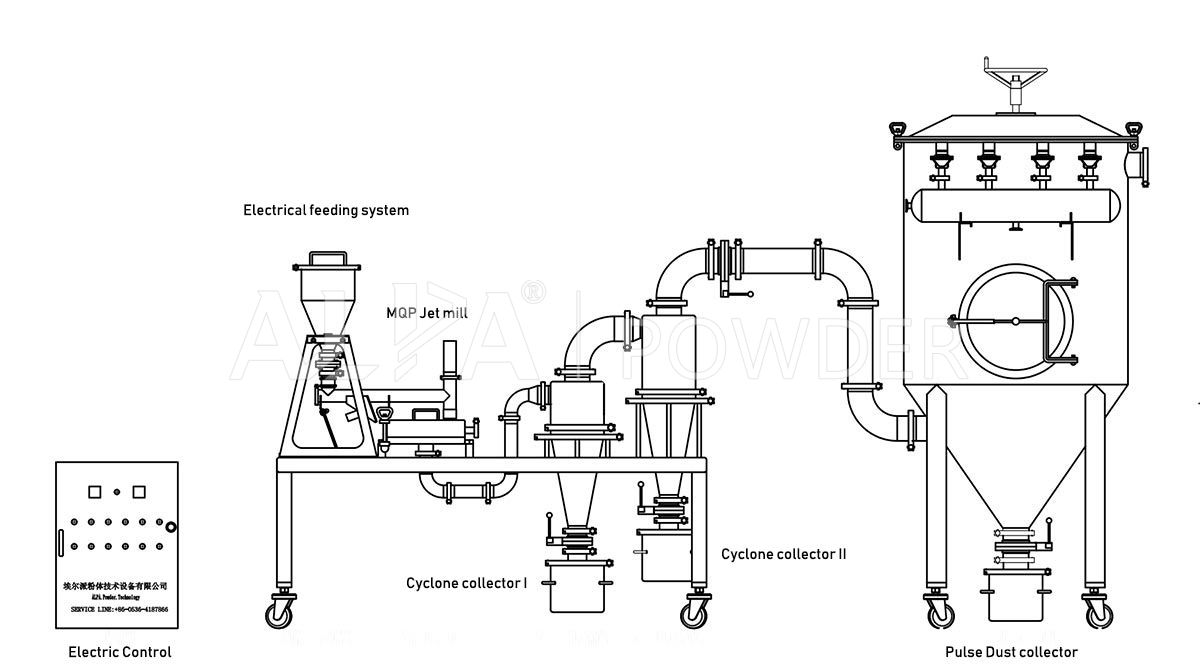

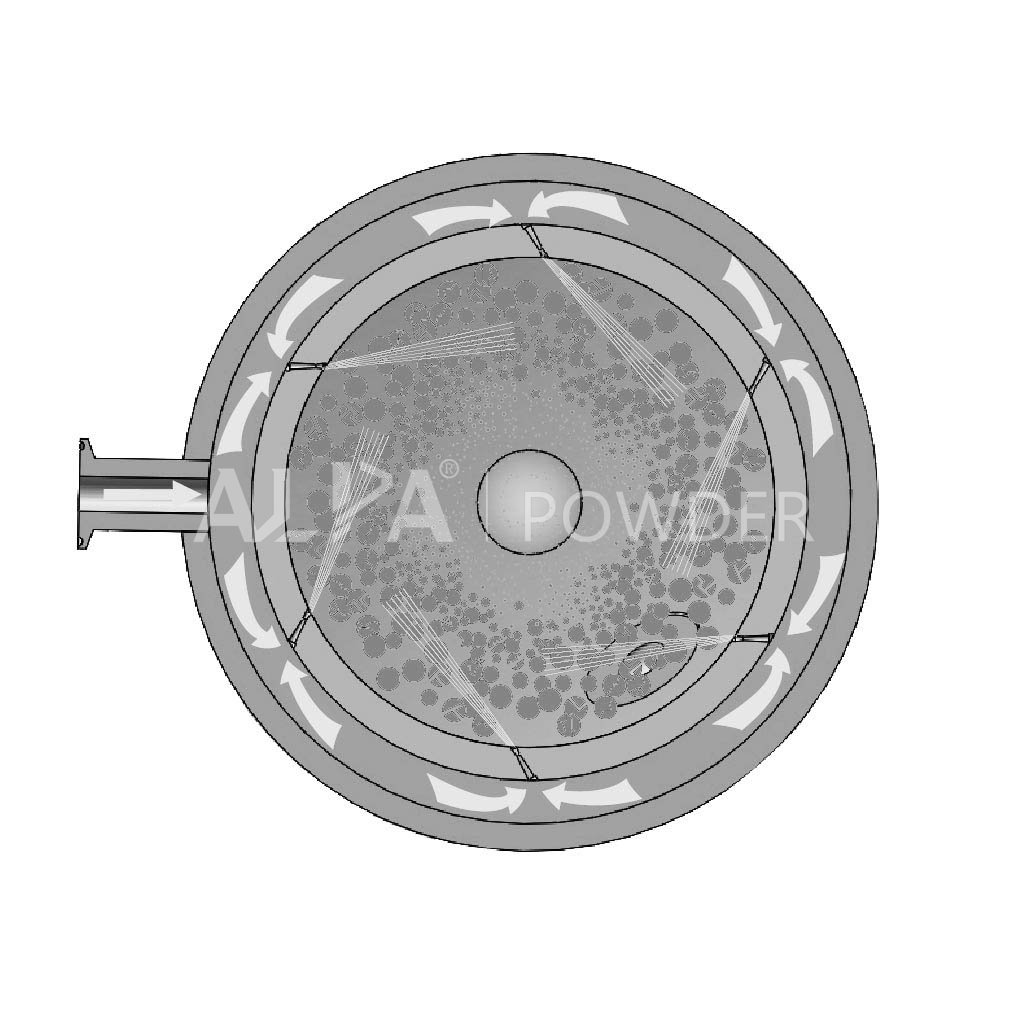

Pharmaceutical jet mill(Medical jet mill,Pharmacia jet mill,pharmacy jet mill) works with cyclone separator, dust collector and suction fan to form a complete grinding system. Compressed air flow after filtration and drying would go into milling chamber from nozzles, and meet in the center area, where material would be impacted and ground and sheared. Milled powder would go up to the classifying chamber by the air flow from suction fan. The high-speed rotation of classifier wheel would create a strong centrifugal force to separate coarse powder and fine powder. Qualified fine powder would go through the wheel vane then into the cyclone separator or dust collector, while mixture of coarse powder and fine powder would fall down to the milling chamber to be milled again.

Technical Parameters

| Parameters/specifications | MQP03 | MQP06 | MQP10 | MQP20 | MQP40 | MQP60 | MQP80 |

|---|---|---|---|---|---|---|---|

| Feed Size(mm) | <5 | <5 | <5 | <5 | <5 | <5 | <5 |

| Product Size(d97:um) | 8~150 | 8~150 | 8~150 | 8~150 | 10~150 | 10~150 | 10~150 |

| Production Capacity(kg/h) | 5~100 | 10~200 | 20~400 | 50~800 | 150~1500 | 300~2000 | 400~6000 |

| Air consumption(m3/min) | 3 | 6 | 10 | 20 | 40 | 60 | 80 |

| Air Pressure(Mpa) | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 | 0.7~0.85 |

| Installed Power(kw) | 26~37 | 47~68 | 68~106 | 145~184 | 276~310 | 402~427 | 520~600 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

Related Engineering Case

Applications and Services

Applicable material

This equipment is widely used in the pharmaceutical industry Urotropine, ibuprofen, theophylline, cilostazol, vitamin C, black cohosh, carbamazepine, vinasse, nimodipine, Turtle powder, fenofibine, acyclovir, albendazole, nimodipine, chlorhexidine, meloxicam, fenofibrate, amoxicillin, aprovir, albendazole, salbutamol, hydrogenation Pine, oxytetracycline, indomethacin, mefenamic acid, primidone and other raw materials.