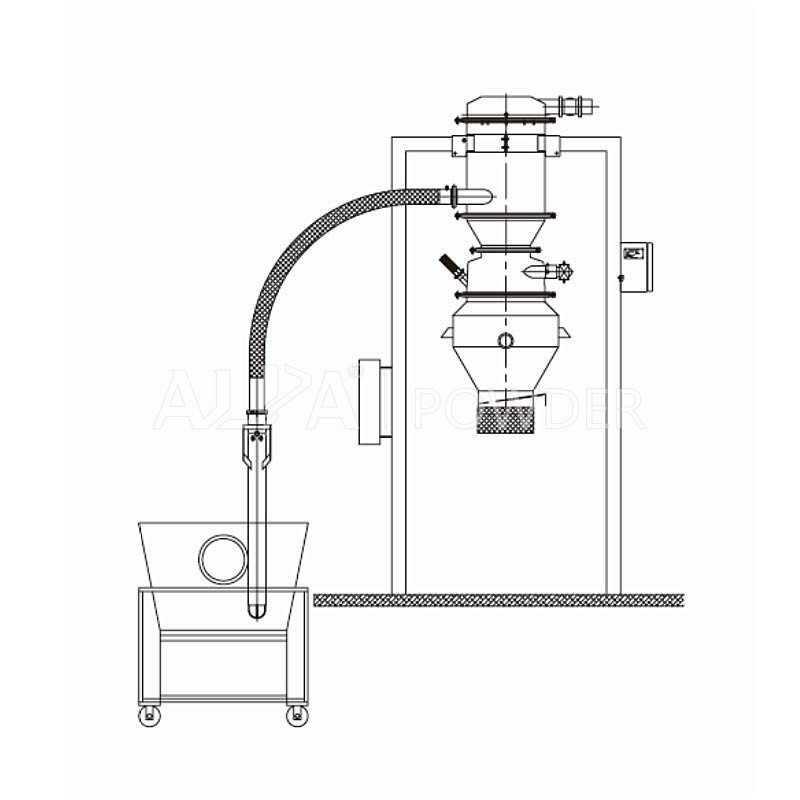

AVC Series Vacuum Conveyor

Suitable for the tight transfer of powder materials, granules, tablets, capsules and other powder materials between different parts of production line, preventing cross-contamination between materials and environment, and protecting labor. Suitable for pharmaceutical, food, chemical and other industries.

Technical Parameters

| Parameter | Delivery Volume | Vacuum Source Consumption | Compressed Air Consumption | Diameter |

|---|---|---|---|---|

| Compressed Air | ||||

| AVC-180A | <375 | N/A | 36 | 180×580 |

| AVC-200A | <525 | N/A | 60 | 210×580 |

| AVC-200B | <750 | N/A | 60 | 210×630 |

| AVC-200C | <1100 | N/A | 60 | 210×680 |

| AVC-300C | <1600 | N/A | 110 | 330×940 |

| AVC-300D | <2000 | N/A | 110 | 330×990 |

| AVC-300E | <2400 | N/A | 110 | 330×1040 |

| AVC-500E | <4900 | N/A | 220 | 500×1360 |

| Negative Pressure Source | ||||

| ZVC-200A | <625 | 126 | N/A | 180×580 |

| ZVC-200B | <900 | 144 | N/A | 210×696 |

| ZVC-200C | <1250 | 162 | N/A | 180×580 |

| ZVC-300C | <1800 | 198 | N/A | 330×1050 |

| ZVC-300D | <2200 | 216 | N/A | 330×1100 |

| ZVC-300E | <2600 | 234 | N/A | 330×1090 |

| ZVC-500E | <5300 | 390 | N/A | 500×1360 |

| Remark | Test conditions: material specific gravity 0.8-1.0, horizontal conveying distance 5 meters, vertical conveying distance 2 meters, the material fluidity is good. | |||

| Filter material: 1.titanium metal sintering; 2. stainless steel sintering; 3. coated knit felt; 4. polytetrafluoroethylene PTFE. | ||||

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

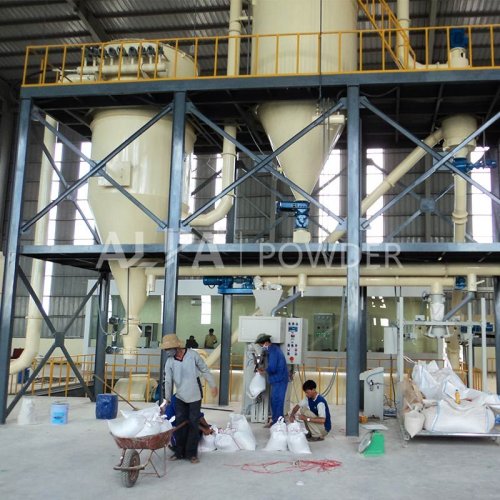

Related Engineering Case

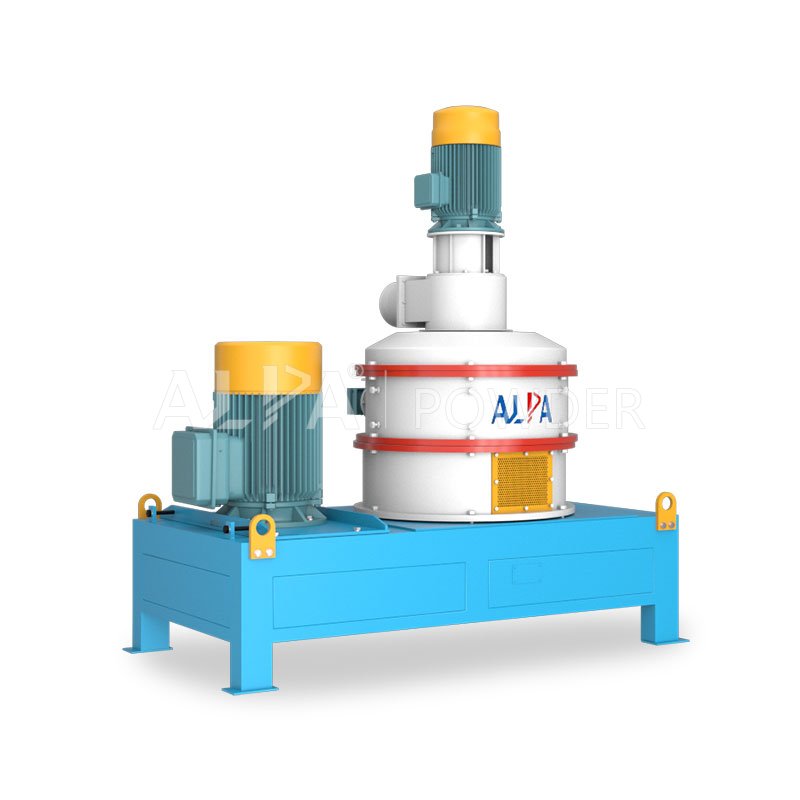

Applications and Services