OUR PRODUCTS

ALPA,the world’s leading provider of ultra-fine powder solutions.

With 18 years of focus on ultra-fine ultra-pure crushing and classifying research, powder shape control and selective crushing,powder surface modification, and system integration of powder engineering equipment.

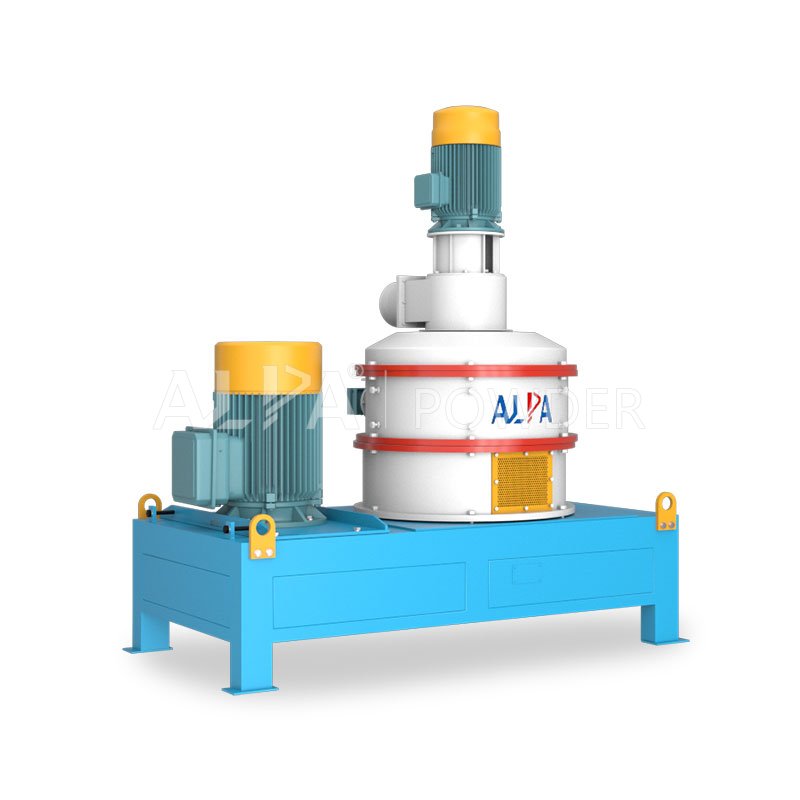

Jet Mill

The first Chinese large-scale Jet Mill MQW160 (gas consumption 160m³/min). There are two types of vertical and horizontal structures to meet the needs of different grinding and classifying requirements.The German technology, automation control design, meet requirements of Industry 4.0.

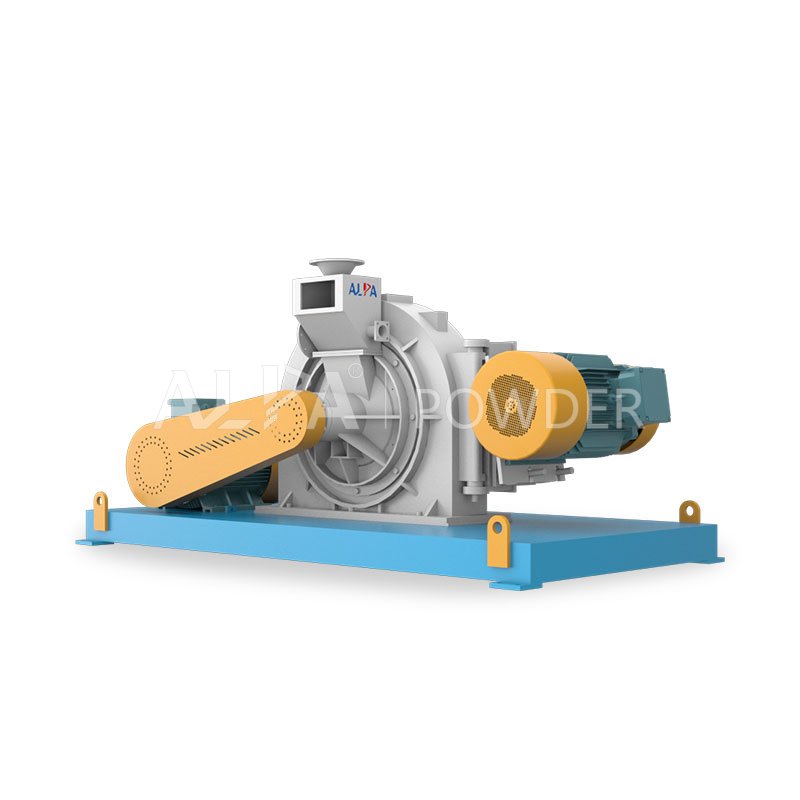

Impact Mill

According to the material characteristics requirements, can be customized and widely used for fine grinding and superfine grinding of chemical, pharmaceutical, food, mineral, building materials and other materials. The particle size range is 20mesh ~ 3000mesh, Production capacity is 5kg/h ~ 5000kg/h. Cold air, air circulation and nitrogen circulation processes are available.

Steam Jet Mill

High grinding energy, high efficiency and energy saving, could produce nanometer material, explosion-proof, negative pressure environmental protection, high degree of automation, low noise, small footprint and simple installation. The nano-scale/sub-micron grinding of dry process can be realized, the problem of large viscous force and product agglomeration can be solved.

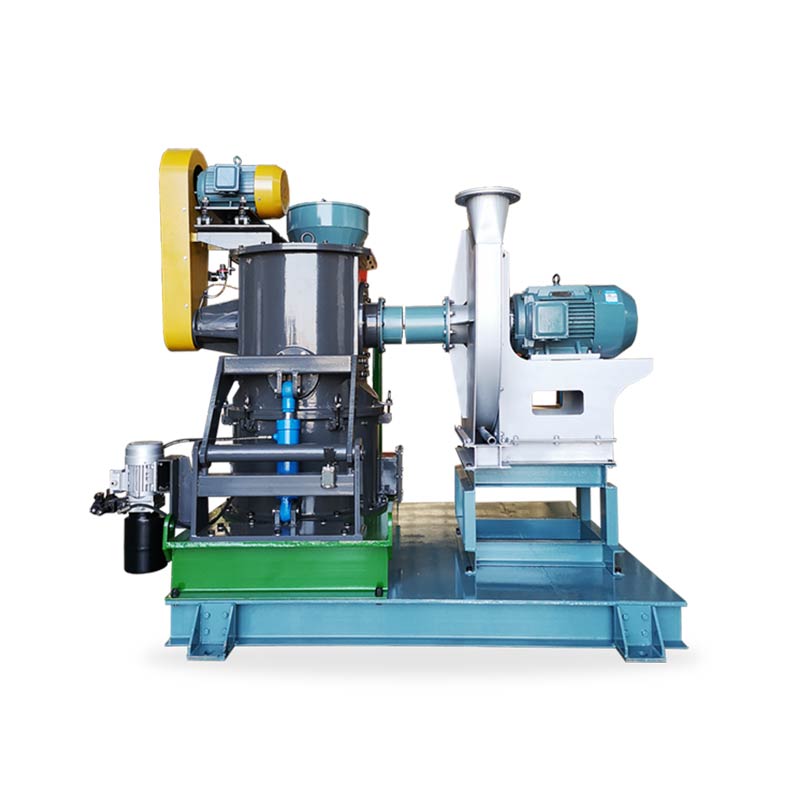

Laboratory Equipment

The first three-in-one combined structure, flexible Jet Mill, Air Classifier, Impact Mill in one. Compact structure, high efficiency gas seal, small footprint, PLC control, easy operation and wide application. Easy to disassemble and clean. Can be applied to a variety of grinding processes.

Powder Coating Equipment

Adopting the most popular Coating process, with wide application range, less modifier, high coating rate, high degree of automation, flexible production process, environmental protection and energy saving, rich equipment selection and customizable solutions.

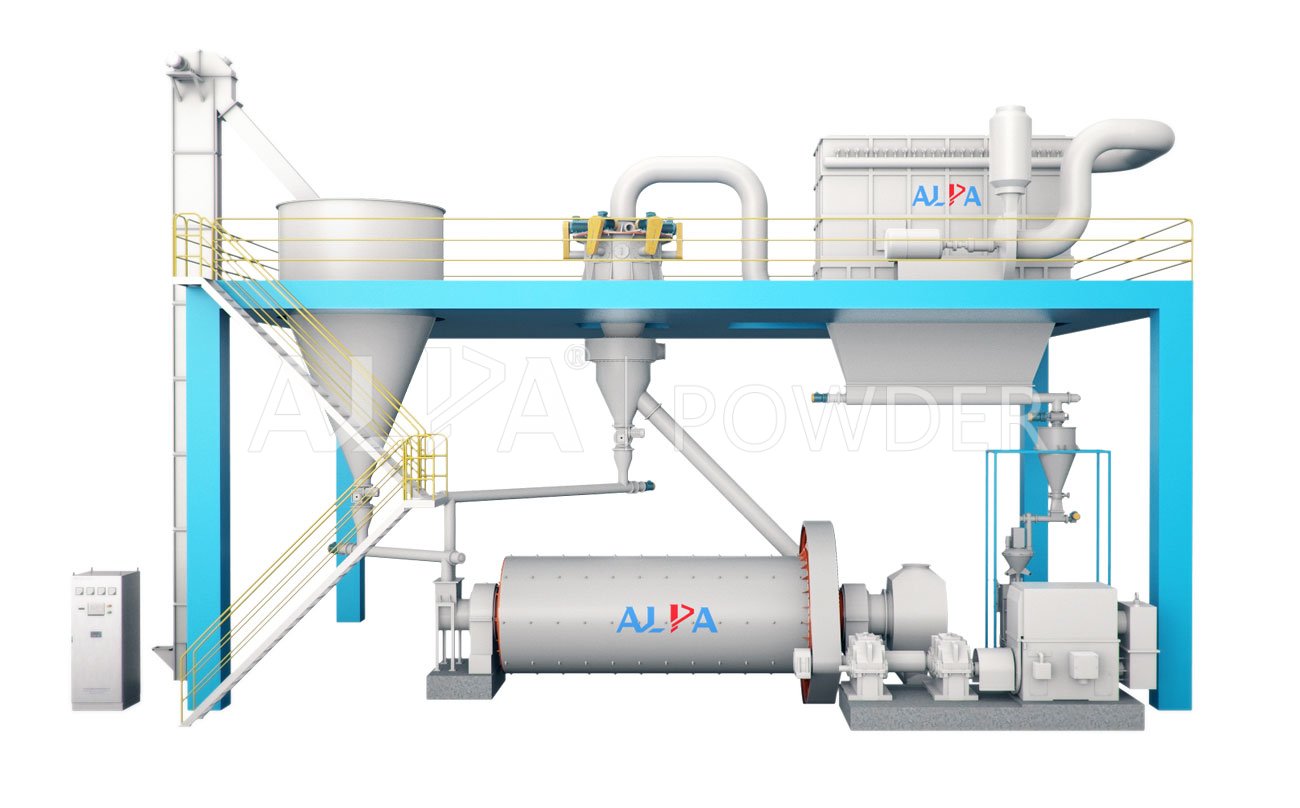

Classifying and Ball Mill Production Line

The world’s leading technology, mature technology, stable operation, low maintenance cost, low unit energy consumption, flexible selection of grinding media and liners, high-purity processing, concentrated product size distribution and customizable solutions.

Auxiliary Equipment

It can be used together with various types of Jet Mill, Impact Mill and Classifiers, can design and equipments for vacuum conveying, quantitative dosing, dust-free feeding, iron removal, automatic packaging and other units according to requirements of the powder process. Can meet requirements of closed operation for materials in the pharmaceutical, food, chemical and other industries.