QUALITY CONTROL

ALPA’s quality assurance goal is to pursue the zero defects of all manufactured ultra-fine powder equipment, actively implement Six Sigma quality management, and continuously improve process control management capabilities through advanced statistical analysis of data to create products and services that satisfy customers.

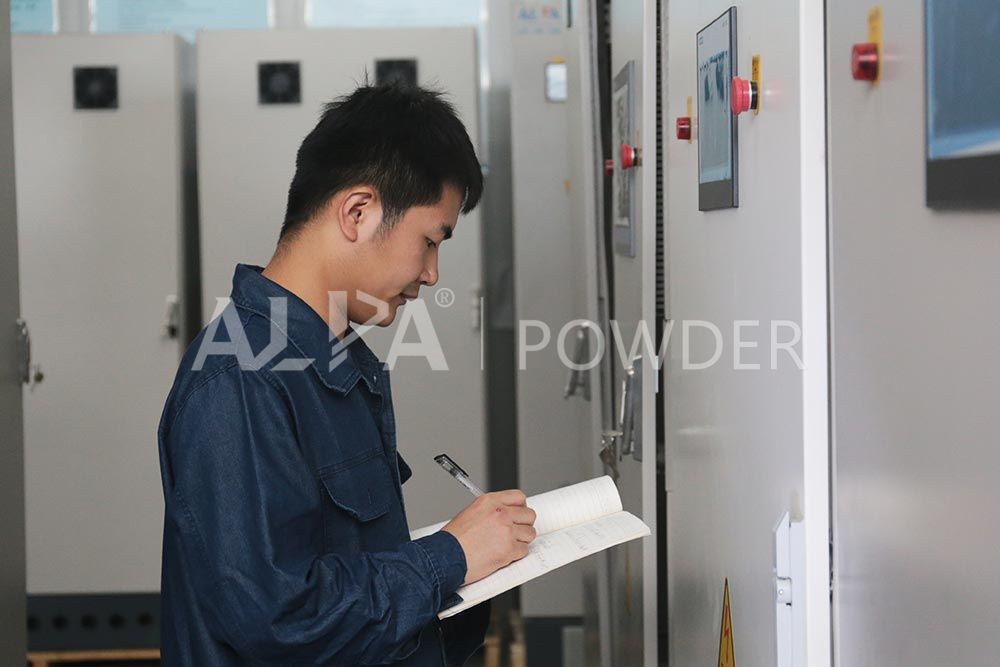

Factory management

ALPA uses the advanced ERP system to standardize the management of the factory, realize the simultaneous monitoring of the entire manufacturing process, and effectively improve production efficiency.Implement warehousing barcode management system and supply chain management system to manage factories and warehouses in a unified manner and actively respond to manufacturing needs.

ERP system

In 2010, the company began to implement the ERP project. After several years of development, it realized synchronous engineering and meticulous production. The production supply chain maintenance, financial resource allocation, human resource allocation, etc., all were optimized and managed, which is bound to bring the ALPA resource management system to the world’s advanced level.

Warehousing barcode management system

Starting from the purchase order, material storage,material use,product storage, to the delivery,all use the barcode to tracking and management.ALPA warehouse barcode logistics management system is based on advanced bar code technology, Starting from the purchase order, material storage,material use,product storage, to the delivery,all use the barcode to tracking and management. The application of ALPA warehouse barcode management has established a target management information system for warehouse, effectively assisting in solving problems in inventory and delivery management during production.

Supply chain management system

In order to ensure product quality, ALPA implements strict supplier management, exports technology and management methods to suppliers, and supervises suppliers to strengthen quality control and improve product quality awareness. ALPA establishes a global procurement system, implements global sourcing, shortens lead times, and reduces production costs. ALPA implements product lifecycle quality tracking management, tracking all parts supplied by suppliers, discovering quality problems, finding causes, and tracking accidents.

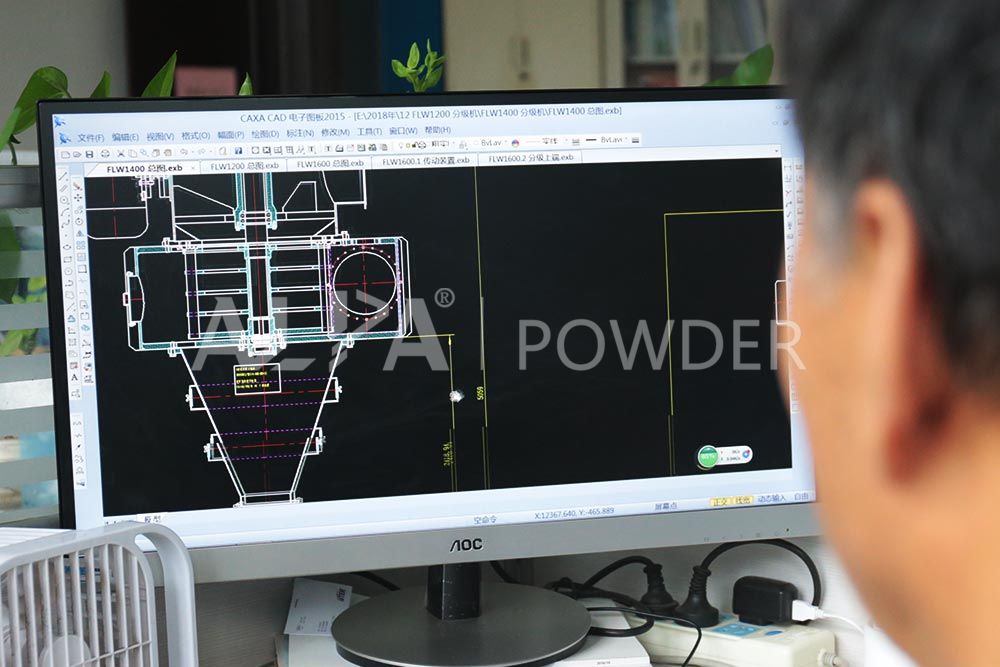

Process control

The assembly process of ALPA consists of 18 manufacturing and inspection processes. From design to procurement, from picking to assembly, from inspection to qualified storage, we have developed a very detailed and rigorous control process at every stage of work to ensure that every product, every link, every step are good and considerate .

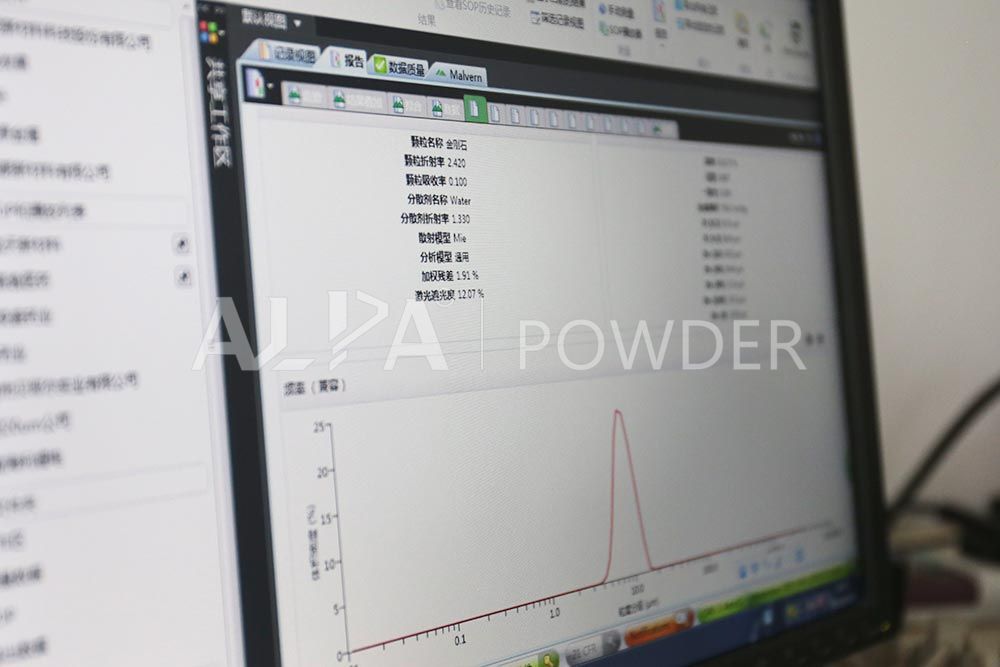

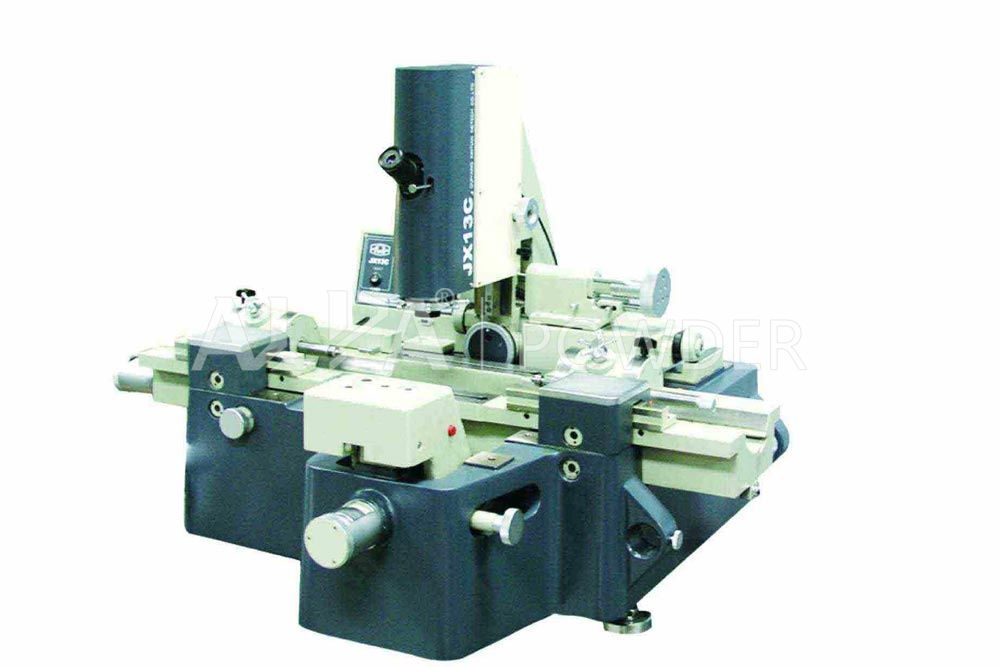

Testing equipment

ALPA pursues advanced scientific research technology and strict quality control. It has many advanced testing instruments, carries out strict quality control on all aspects of production and processing, and strives for perfection, so that customers’ ultra-fine powder processing is stable and smooth.