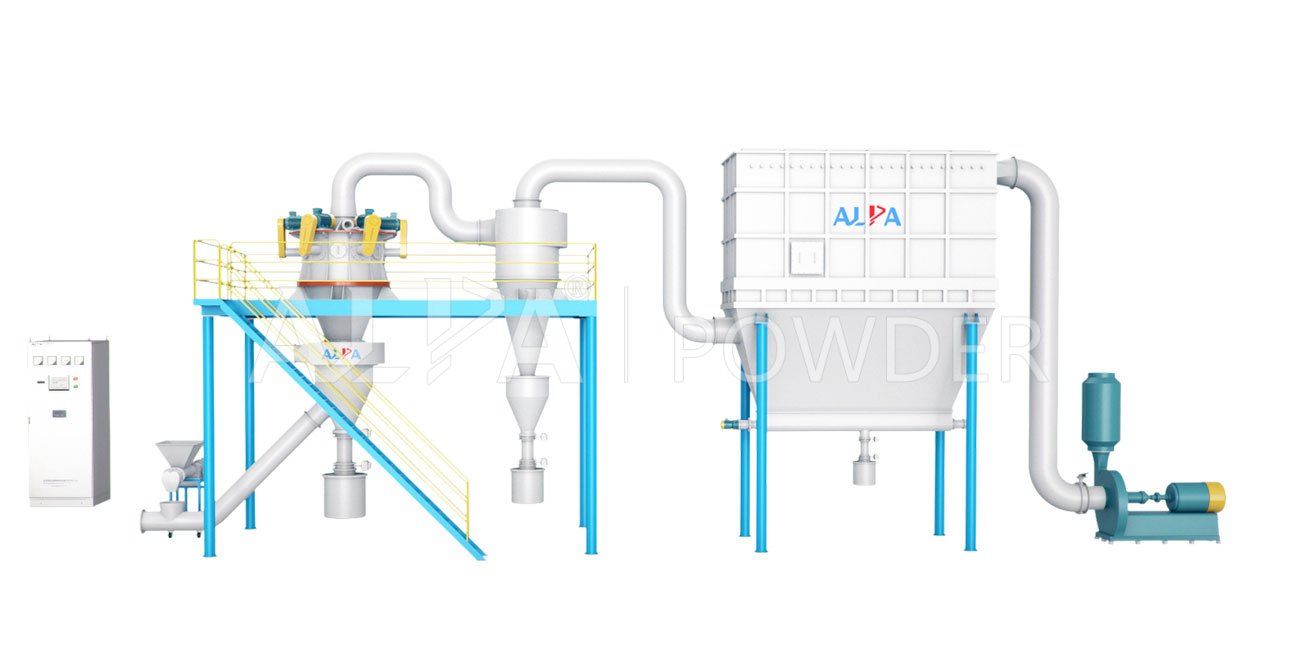

FW/HTS Horizontal Air Classifier

Single Rotor / Multiple Rotor

Widely used in chemical industry, minerals (especially suitable for non-mineral materials classifying, such as calcium carbonate, kaolin, quartz, talc, mica), metallurgy, abrasives, ceramics, refractory materials, medicines, pesticides, food, health products, new materials, etc. industry.

- Available D50:1.5-25μm

- Suitable for precise classifying of dry micron material,, can classify spherical, flaky, needle-like particles, and can also classify particles of different densities

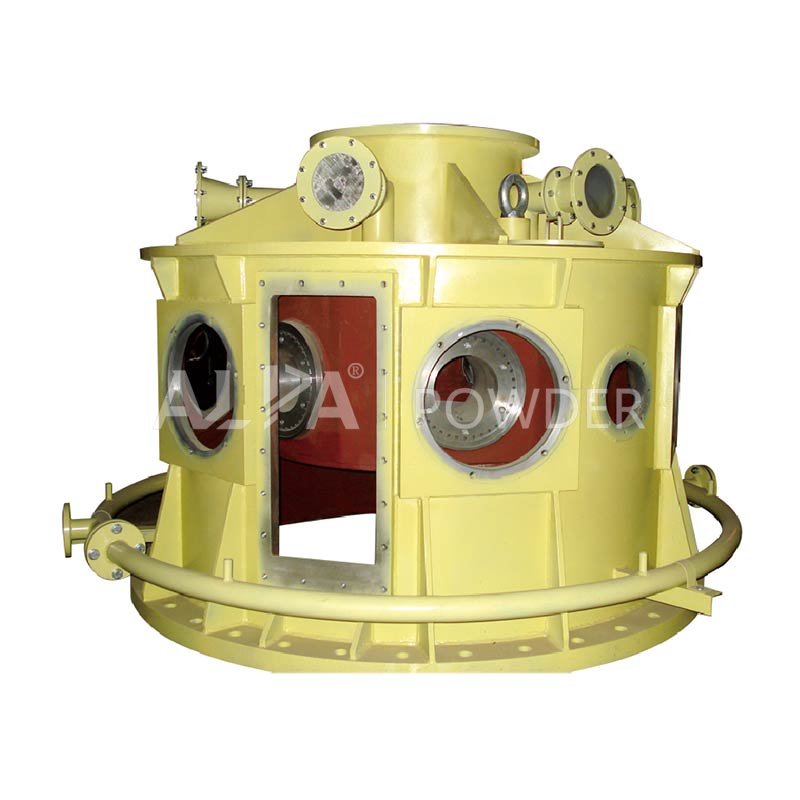

- The linear velocity of horizontally installed classifying wheels is up to 80m/s.

- Classifying efficiency (extraction ratio) can be 60%~90%.

- Speed of wheel is equipped with velocity sensor and can be controlled by inverter, particle size can be adjusted freely.

- Horizontal classifier wheel with high speed and accurate vertex cutting.

- System negative pressure operation, meet environmental requirements, noise <76dB(A).

- The classifying wheel can be made of ceramic materials such as alumina, zirconia and silicon carbide, without metal pollution, meeting the requirements of high-purity materials.

- Grinding is completed in closed system, little dust, low noise in a clean and environmentally friendly process.

- PLC control system, easy operation.

- In conjunction with ball mill, table roller mill and Raymond mill to form closed circulation.

- The motor can be connected with a belt, which is stable and reliable, realizes high speed and increases the speed, and breaks through the problem that the well-known motor brand does not have a high-speed motor.

- Optional explosion-proof design, can also be upgraded to a nitrogen circulation system to meet the processing needs of flammable and explosive oxide materials.

FW/HTS Horizontal Air Classifier

Working Principle

The classifier and cyclone separator, dust collector and induced draft fan form a classifying system.Under the action of fan suction, the material is moved from the lower inlet of the classifier to the classifying zone with the ascending airflow. Under the strong centrifugal force generated by the high-speed rotating turbine, the materials are separated and the fine particles which meet size requirements through the classifier impeller gap into the cyclone separator or the dust collector, the coarse particles entrained part of the fine particles collided with the wall and the velocity disappeared, descending along the cylinder wall to the secondary air outlet, and the coarse and fine particles were separated by the strong washing action of the secondary air. The fine particles rise to the classification zone for secondary classifying, and the coarse particles are lowered to the discharge port for discharging.

Multiple Classifying Wheel working principle Video

Single Classifying Wheel working principle Video

FW/HTS Horizontal Air Classifier

Technical Parameters

Multiple Rotor

| Parameters/specifications | FW400/3 | FW400/4 | FW630/3 | FW630/4 | FW630/6 | FW800/4 | FW800/6 | FW1000/4 | FW1000/6 |

|---|---|---|---|---|---|---|---|---|---|

| Production Capacity(T/h) | 0.2~1.5 | 0.3~2 | 1~5 | 2~8 | 3~10 | 3~10 | 5~15 | 5~20 | 8~30 |

| Product Size(d97:um) | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 5~45 | 5~45 | 5~45 | 5~45 |

| Classifying efficiency(%) | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 |

| Installed Power(kw) | 60~90 | 175~100 | 135~155 | 170~190 | 250~290 | 220~290 | 290~390 | 340~440 | 500~580 |

Single Rotor

| Parameters/specifications | FW200 | FW280 | FW400 | FW520 | FW630 | FW800 |

|---|---|---|---|---|---|---|

| Production Capacity(kg/h) | 10~100 | 20~200 | 50~500 | 100~1500 | 200~2500 | 400~4000 |

| Product Size(d97:um) | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 5~45 |

| Classifying efficiency(%) | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 | 60~80 |

| Installed Power(kw) | 7~11 | 15~19 | 21~28 | 23~30 | 52~60 | 67~77 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

FW/HTS Horizontal Air Classifier

Album

FW/HTS Horizontal Air Classifier

Related Engineering Cases

“I don’t know how to choose the best for me.”

IT DOESN’T MATTER

LET US HELP YOU!

The raw material and the particle size, output, and application industry of the finished product determine the choice of equipment and process. As an expert, you will not be unfamiliar with this.If you have any questions, don’t worry, please leave us a message, or “Live Chat” in the lower corner of this page, or contact us via our phone or email.

ANY QUESTIONS OR DEMANDS

PLEASE CONTACT US RIGHT NOW!

Learn More & Get Quotation

Please tell us your needs.

Our engineer will send you solutions and quotes for free.

Or email