- Available D50:1.5~45μm

- Relying on the grinding roller orbital revolution and rotation on the grinding ring track to finish grinding.

- Compared with Raymond mill or ball mill, the production efficiency is more than doubled under the same dynamic conditions,lower operating cost.

- Large output: grinding calcium carbonate, the fineness is 10μm, the output can reach 3 tons / hour or more

- Good product fineness index: can reach the fineness of fluidized bed jet mill, D97: 3 ~ 45μm

- Built-in classifying wheel

- It is equipped with classifying wheel frequency control, which can adjust the granularity of the product without stopping the machine.

- Unique structure of classifying impeller, favorable classifying effect and no particle pollution.

- Favorable product granularity and stability,Ideal equipment for current dry grinding method to produce non-metallic mineral fine powder such as calcium carbonate.

- The complete set of equipment is easy to install and does not require large civil works.

- Fine powder can be completely recycled without polluting the environment.

- Compact structure and small occupation.easy to disassemble and clean

- Lower installation power, wide application, high cost-performance.

- Grinding is in closed system, low dust and noise, clean and environmentally friendly production process.

- PLC control system, easy operation.

- Particle sizes can be adjusted as needed.Could produce powder of D97: 3-8μm, and also produce ordinary powder of D97: 10-40μm.

- Can be used in series with multi-stage classifiers to produce products with multiple sizes at one time.

- Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials.

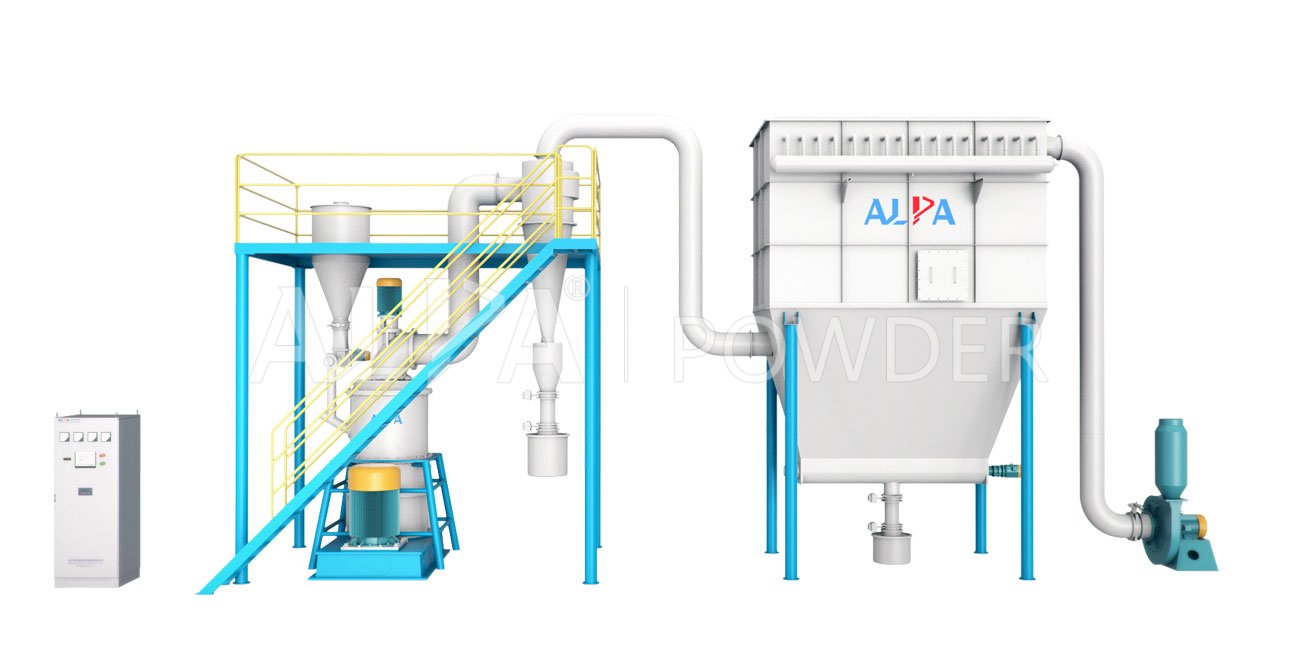

RLM Ring Roller Mill

Working Principle

Roller mills(micro powder roller mill,fine roller mill,ring roller mill,roller grinding machine,automatic roller mill,three/four roller/rolling mill) are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others. Roller grain mills are an alternative to traditional millstone arrangements in gristmills. Roller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the mining and processing of ore and construction aggregate; cement milling; and recycling.

Transmission device connects with main shaft. The top of shaft connects with rotor structure. The rotor structure has peripheral shaft. Peripheral shaft is installed with roller. When the main shaft starts to rotate, peripheral shaft rotates too, which would make the rollers revolve around main shaft and also rotate round peripheral shaft. The roller would create strong centrifugal force during the rotation and revolving, and grind material with stator. The ground material would fall down to the distribution plate. The distribution plate and the main shaft would rotate at the same time, and bring material to the round ring. Under negative pressure, it would go along the distribution ring to the classifier chamber. Qualified fine powder would go through the classifier wheel and into the collector, while coarse powder would fall down back to the milling chamber for further grinding.

ALPA is a rolling mill manufacturer that produces various types of mills.

RLM Ring Roller Mill

Technical Parameters

| Parameter | RLM89 | RLM189 | RLM219 | ||||

|---|---|---|---|---|---|---|---|

| Size | D97 | Output(kg/h) | kwh/ton | Output(kg/h) | kwh/ton | Output(kg/h) | kwh/ton |

| 600 | 28um | 4500~5000 | 30 | ||||

| 800 | 18um | 2500~2800 | 43 | 3500~4200 | 42 | 3500~4200 | 40 |

| 1250 | 10um | 1500~1800 | 67 | 2000~2500 | 75 | 2000~2500 | 72 |

| 1500 | 9um | 1000~1300 | 92 | 1500~2000 | 95 | 1600~2100 | 92 |

| 2000 | 7.8um | 650~750 | 125 | 1000~1500 | 113 | 1100~1600 | 110 |

| 2500 | 5.5um | 600~650 | 135 | 800~1200 | 123 | 900~1300 | 119 |

| POWER | 152kw | 237kw | 237kw | ||||

| Note | The above data is based on heavy calcium (feed size <10mm, Mohs hardness <5%), affected by different materials, differences in production areas etc, above data is for reference only. The particle size was measured by Omega particle size analyzer and Malvern particle size analyzer. | ||||||

RLM Ring Roller Mill

Album

“I don’t know how to choose the best for me.”

IT DOESN’T MATTER

LET US HELP YOU!

The raw material and the particle size, output, and application industry of the finished product determine the choice of equipment and process. As an expert, you will not be unfamiliar with this.If you have any questions, don’t worry, please leave us a message, or “Live Chat” in the lower corner of this page, or contact us via our phone or email.

ANY QUESTIONS OR DEMANDS

PLEASE CONTACT US RIGHT NOW!

Learn More & Get Quotation

Please tell us your needs.

Our engineer will send you solutions and quotes for free.

Or email