Working Principles

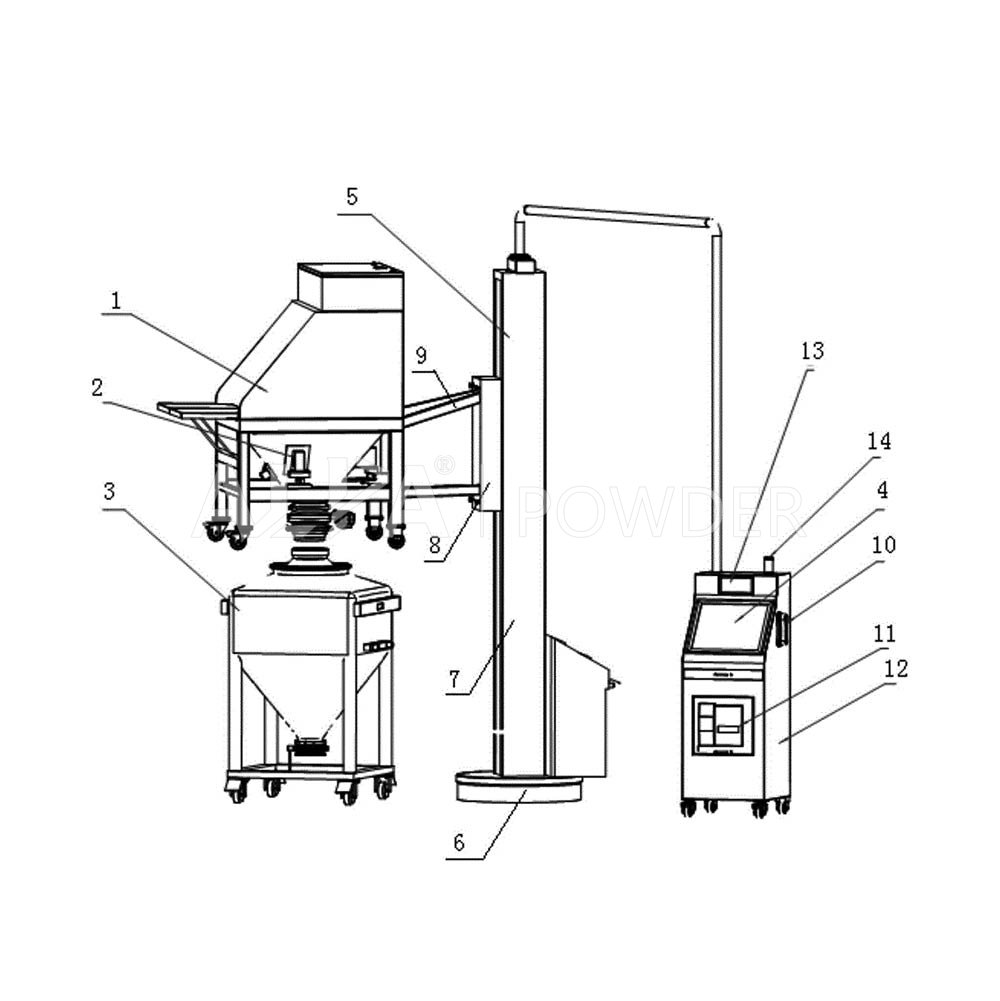

Small bag packaging:

Artificially breaking bag, one button to start the feeding station to assist the flap lifting mechanism, so that the material enters the hopper by gravity.

Bag packaging:

Lifting the bag to the top of feeding station, manually unpacking or automatically unpacking, material enters the feeding station by gravity.

Technical Parameters

| Parameter | Power(kw) | Cache Volume(L) | Overall Size(mm) | Remark |

|---|---|---|---|---|

| DFS-100 | 0.25 | 100 | 1500x800x1700 | Bag/Barrel |

| DFS-200 | 0.5 | 200 | 1500x800x1850 | Bag/Tons Loading/Barrel |

| DFS-500 | 0.75 | 500 | 1800x1000x2000 | Bag/Tons Loading/Barrel |

Note: The above models can be non-standard design according to customer needs, which can meet the various needs of customers.