ALPA’s Ultrafine Mill

MQW Fluidized Bed Jet Mill

MQL Fluidized Bed Jet Mill

MQP Spiral / Disc Jet Mill

MQP Pharmaceutical Special Spiral Jet Mill

MQPW Spiral Jet Mill

CSM-V Air Classifying Mill

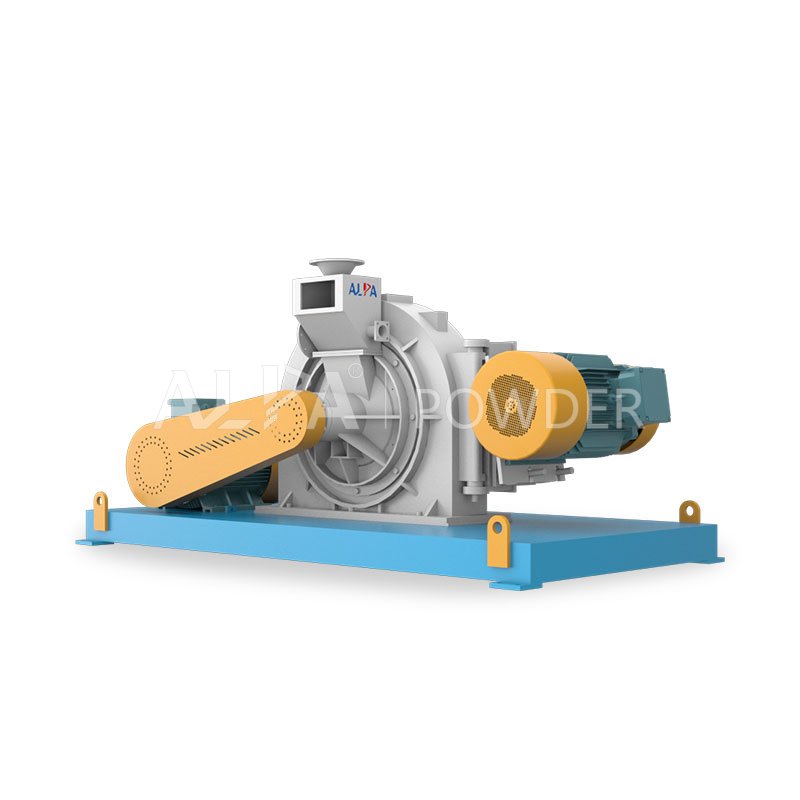

CSM-H Air Classifying Mill

CSM-VD Air Classifying Mill

CSM-HJ Air Classifying Mill

CUM-P Pin Mill

CUM-L Wood Fiber Mill

ULM Turbo Mill

RTM Turbo Mill

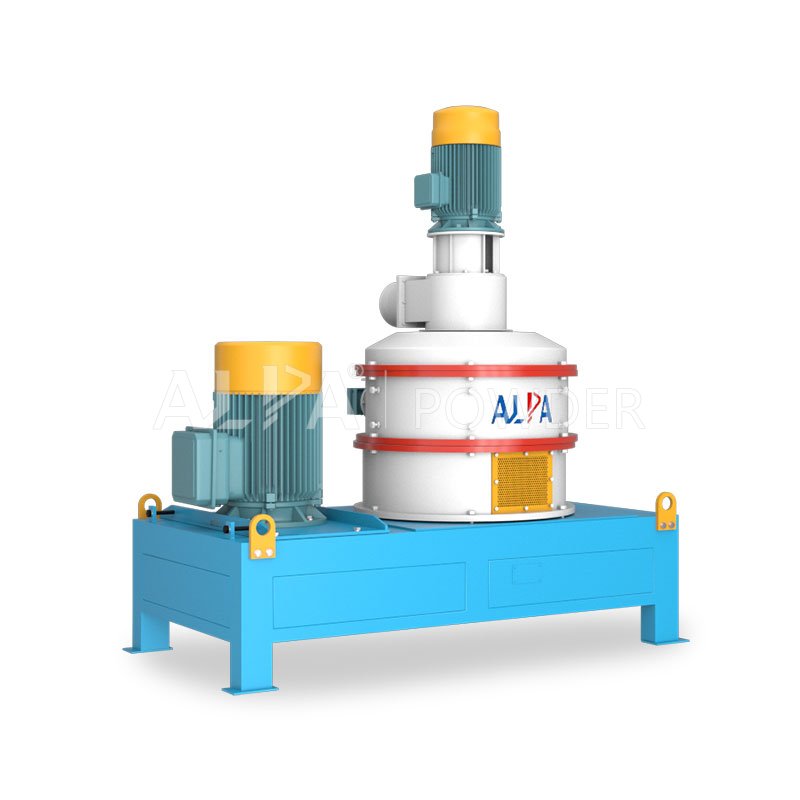

RLM Ring Roller Mill

MZ Herb Vibration Mill

MZ Vibration Mill

TSM Special grinding mill for Sodium bicarbonate

325-5000 mesh (45μm-2.5μm)

Three-In-One Laboratory Mill and Classifier

powder coating and surface modification production line (all)

The most used coating process by the world's mineral magnate/ the minimum dosage of modifier / the best coating effect.

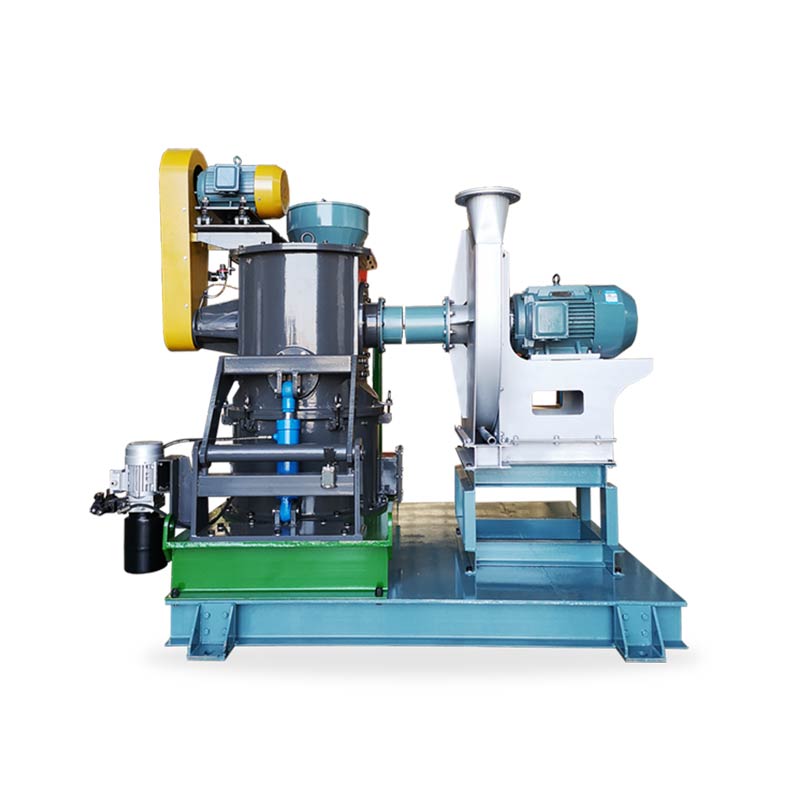

Classifying and Ball Mill Production Line

The world's leading process line / mature technology / green / low energy consumption.

Continuous coating process

Continuous coating process The most used coating process by [...]

Batch coating process

Batch coating process The most used coating process by [...]

Compound coating process

Compound coating process The most used coating process by [...]

CUM-F Hammer Mill

Take you to know

ALPA’s Ultrafine Mill / Ultramicro powder Mill /Ultra-micro Crusher /Ultra-micro pulverizer(micronizer)

ALPA mainly produces ultra fine grinding equipment machines. Including various of Impact mill, Jet mill, Air Classifier.

Our powder micronizing milling machine/acm ultrafine mill ranks first in the industry in China in terms of stability, ease of use and energy saving. Among them, air jet micronizer mill has acquired a number of intellectual property rights.

After nearly 20 years of development and precipitation, we have achieved a leap from product to service, and completed more than 100 turnkey projects – EPC projects for customers in the world, in minerals, pharmaceuticals, food, chemicals, new energy, industry, solid waste, high-tech materials and other fields provide powder materials manufacturers with globally competitive products, processes and advanced “one-stop” solutions

“I don’t know how to choose the best for me.”

IT DOESN’T MATTER

LET US HELP YOU!

The raw material and the particle size, output, and application industry of the finished product determine the choice of equipment and process. As an expert, you will not be unfamiliar with this.If you have any questions, don’t worry, please leave us a message, or “Live Chat” in the lower corner of this page, or contact us via our phone or email.

ANY QUESTIONS OR DEMANDS

PLEASE CONTACT US RIGHT NOW!

Learn More & Get Quotation

Please tell us your needs.

Our engineer will send you solutions and quotes for free.

Or email