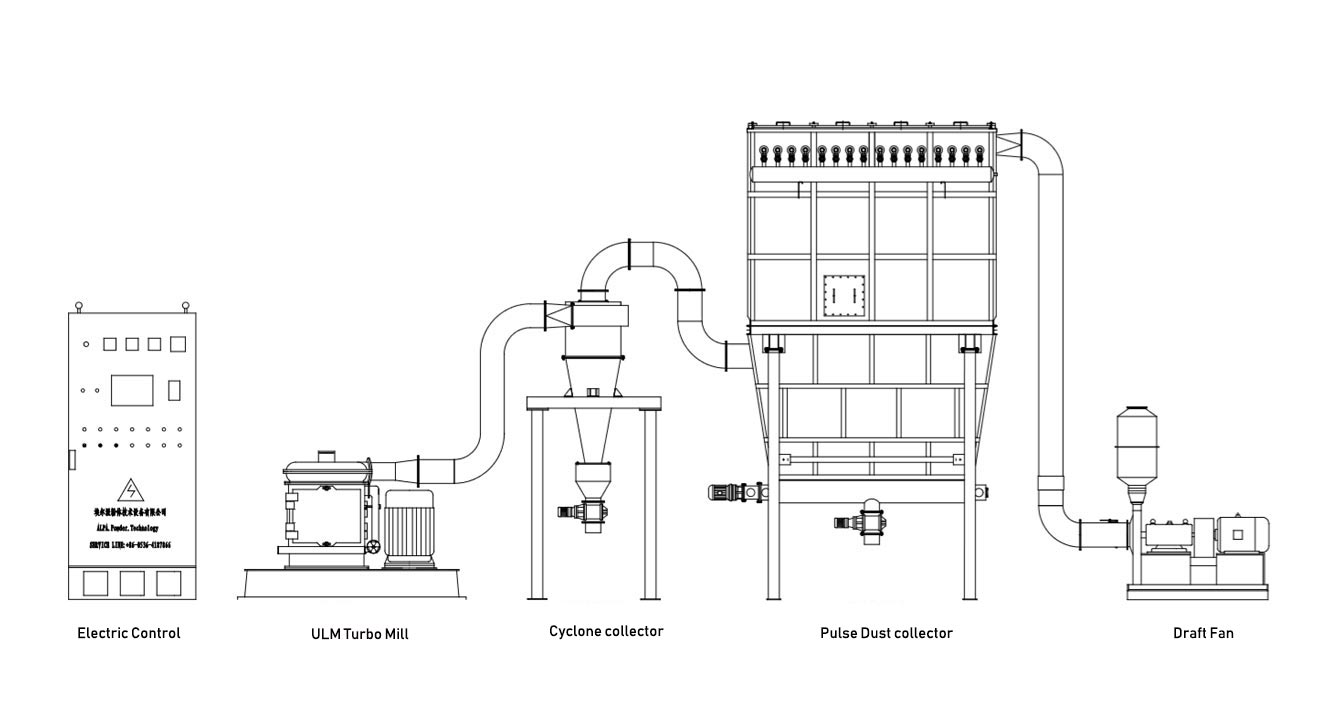

ULM Turbo Mill

Especially suitable for the dispersion and reduction of agglomerated materials, such as: light calcium, kaolin, aluminum hydroxide, magnesium oxide, and ultrafine grinding of heat sensitive materials such as polyvinyl alcohol, PVC, PE, cellulose. Widely used in non-metallic minerals, chemicals, fuel, feed, food and other industries.

- Available D50:3~45μm

- Suitable for raw materials with Moh’s hardness lower than 3, especially suitable for tough materials such as fiber and plastic

- The grinding rotor comprises multi-layer grinding disc and several grinding blades, high grinding efficiency.

- Durable alloy blade, replaceable.

- Distance between the grinding cutter head and the ring gear can be adjusted to adapt to the grinding of different materials

- Compact structure and small occupation. easy to disassemble and clean

- Lower installation power, wide application, high cost-performance.

- Grinding is in closed system, low dust and noise, clean and environmentally friendly production process.

- PLC control system, easy operation.

- External cooling air can be used to achieve low temperature grinding, especial in heat sensitive materials.

- Can be used in series with multi-stage classifiers to produce products with multiple sizes at one time.

- Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials.

ULM Turbo Mill

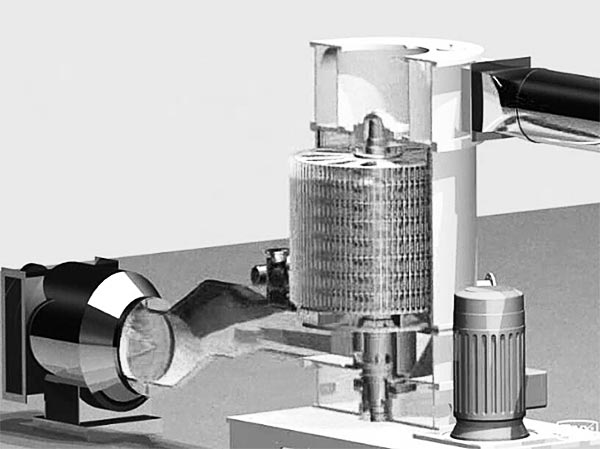

Working Principle

The material is uniformly fed into the grinding zone by feeding system and strongly impacted by the high-speed rotating grinding disc. The grinding rotor is composed of a multi-layer grinding disc and a plurality of grinding blades, the material is subjected to various grinding forces such as shearing, collision, friction etc and finished grinding. The qualified materials are collected into the collection zone with the ascending airflow, the coarse materials are returned to the grinding zone for secondary grinding.

ULM Turbo Mill

Technical Parameters

| Parameters/specifications | Rotor Diameter(mm) | Power (kw) | Rotate Speed(Max r/min) | Maximal Air Volume(m3/h) | Fineness(um) | Output(kg/h) |

|---|---|---|---|---|---|---|

| ULM-400 | 360 | 30~37 | 4600 | 1200 | 15~250 | 30~800 |

| ULM-600 | 540 | 45~55 | 3050 | 2000 | 15~250 | 80~2000 |

| ULM-800 | 730 | 75~90 | 2100 | 3000 | 15~250 | 100~3000 |

| ULM-1200 | 1130 | 110~132 | 1480 | 7500 | 15~250 | 200~4500 |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

ULM Turbo Mill

Album

ULM Turbo Mill

Related Engineering Cases

“I don’t know how to choose the best for me.”

IT DOESN’T MATTER

LET US HELP YOU!

The raw material and the particle size, output, and application industry of the finished product determine the choice of equipment and process. As an expert, you will not be unfamiliar with this.If you have any questions, don’t worry, please leave us a message, or “Live Chat” in the lower corner of this page, or contact us via our phone or email.

ANY QUESTIONS OR DEMANDS

PLEASE CONTACT US RIGHT NOW!

Learn More & Get Quotation

Please tell us your needs.

Our engineer will send you solutions and quotes for free.

Or email